KEMP strives to provide reliable quality by galvanizing and coating each product under mass production conditions.

Through our long experience and know-how, we apply solutions for various conditions.

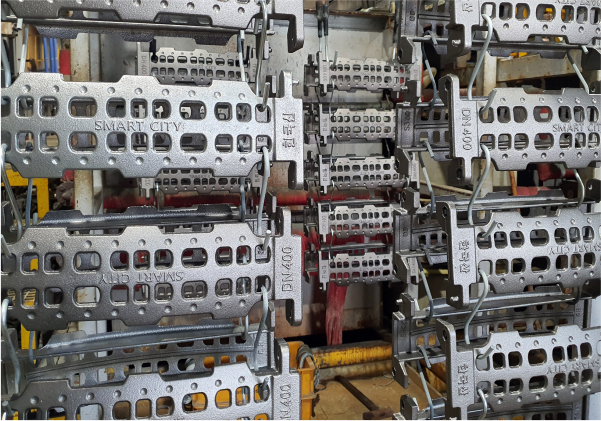

Hang the product on the rack hanger and dip it into the galvanizing bath.

Set the optimal process conditions for galvanizing the inside, outside, and machined areas of the product.

It is the optimal solution when galvanizing of castings is required.

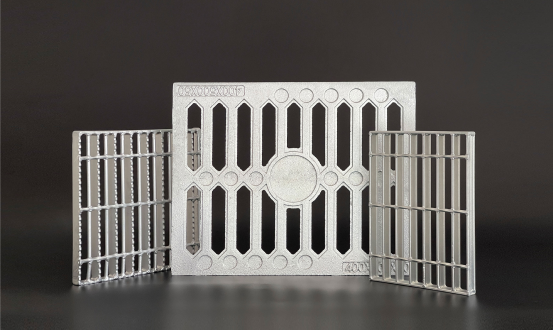

Steel Grating

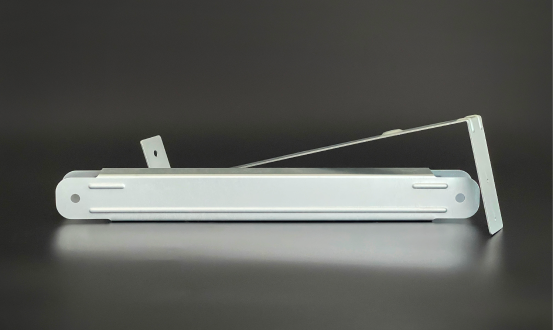

Silent Trench

Caliper Body

Caliper Bracket

Brake Pad

Turnbuckles

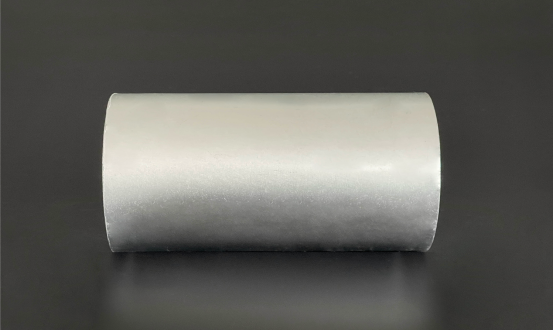

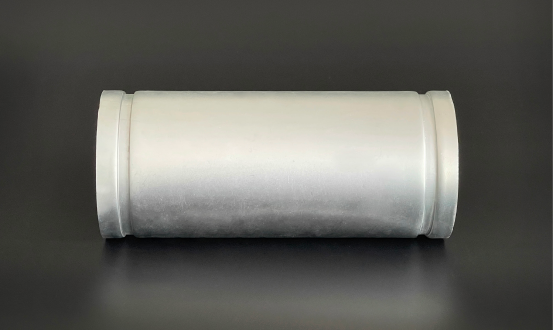

Hang the product on the rack hanger and dip it into the galvanizing bath.

Set the optimal process conditions for galvanizing the inside, outside, and machined areas of the product.

This solution provides the highest level of corrosion resistance through the microscopic attachment of zinc.

Welding Pipes

Grooved Pipes

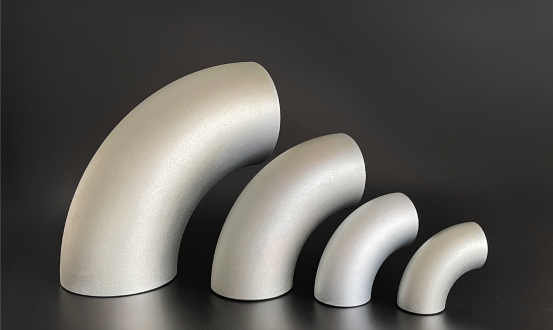

Welding Elbows

Grooved Elbows

Grooved T

Grooved Reducer

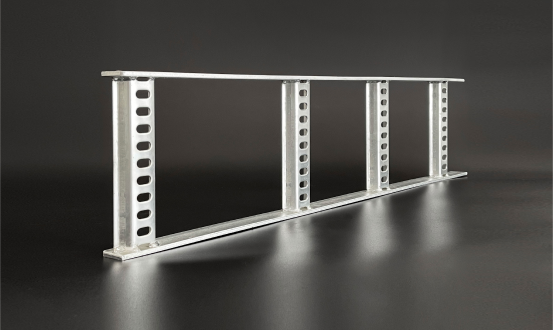

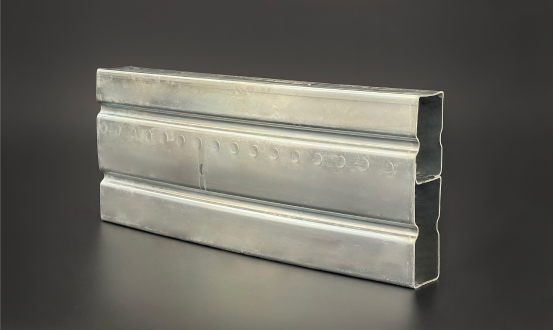

Cable Trays

Solar Structures

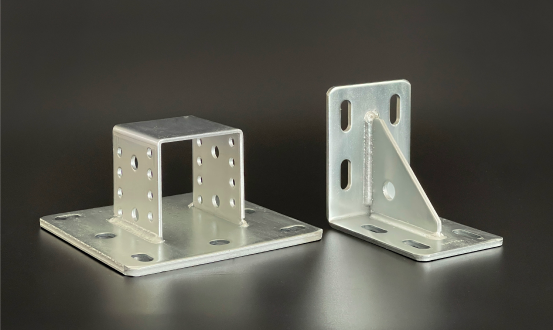

System Channel Bracket

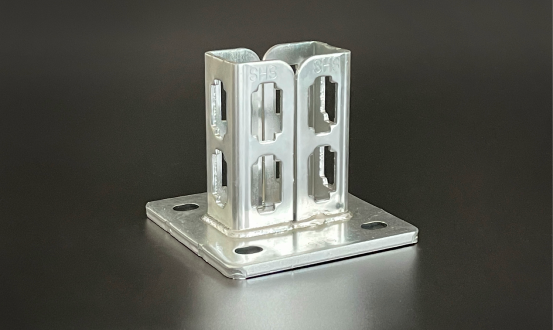

Saddle Flange

Bracket

Locking Rods

Rectangular Tubes

Saddle Clamps

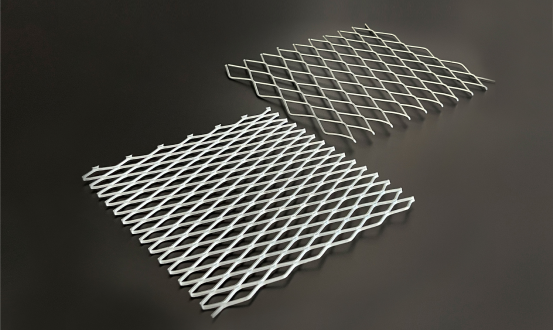

Expanded Metal

U-bolts

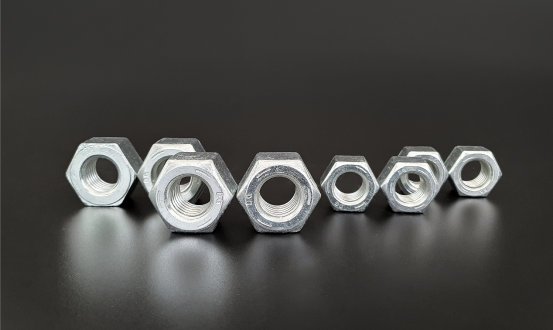

Galvanizing small fasteners.

Establish optimal process conditions for galvanizing fastener threads, thread bones, porosity, etc.

Shipbuilding Bolts

Industrial Bolts

Special Bolts

Special Bolts

Rivets and Inserts (NMI)

Stud Bolts

Nuts

Washers

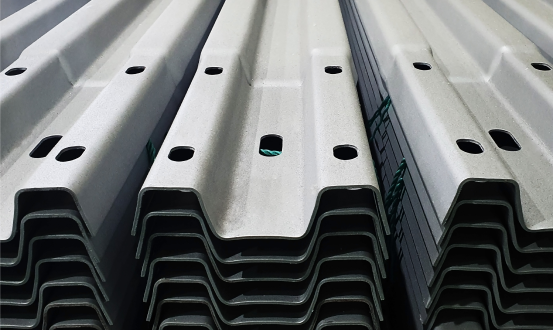

Room temperature curing zinc flake coating that is sprayed directly onto the surface of large steel items such as guardrails.

Coat with equal pressure and time for a stable film thickness.

An optional infrared drying is also available for immediate packaging after coating.

Guardrail

Steel Structure

Wind Generators

Solar Structures

Nuclear power

Transmission towers

Bridges

Railroad Supports

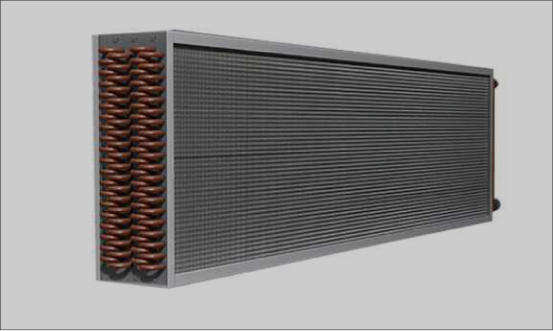

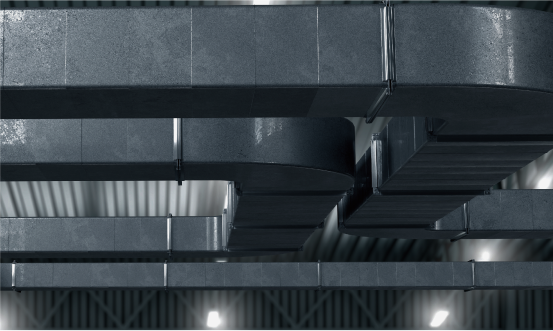

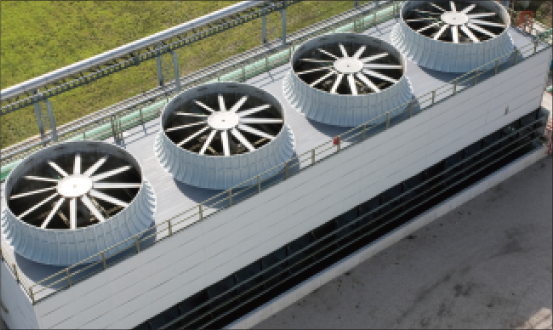

A protective coating process for the pinholes, coils, and casing of air handlers.

It protects against corrosion by coating the exterior and interior of the product.

The surface is complete immediately after drying, enabling fast product packaging and transportation.

AHU

Husing

Coil

Duct

Cooling tower

Unit cooler

Aluminum Die Casting ADC12

A zinc flake coating repair process that repairs corroded guardrails in the field.

Using a hazardous material-free and room temperature curing solution, we provide zinc restoration to old hot-dip galvanizing steel structures.

Prior scheduling consultation is required prior to repair.

Hot-Dip Galvanizing Steel Structure Repair (G·SAVE)

Discover

Galvanizing and Coating processes

Contact us