Hot-dip galvanized guardrail restoration technology

/ Galvanizing repair coatings

Onsite Repair

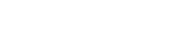

Repairing existing hot-dip

galvanized installations

Dark metallic silver

Zn

Zinc Flake

Coating

Repairing guardrails

Repair corroded galvanizing

Touch-up for welds, cuts

Aerosol

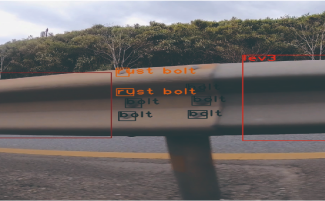

AI Detection

ROC.3 Surface cleaning

G·SAVE application

Construction completed