Korea Eco Metallic Plating

KEMP Technology

Korea Eco Metallic Plating kemp

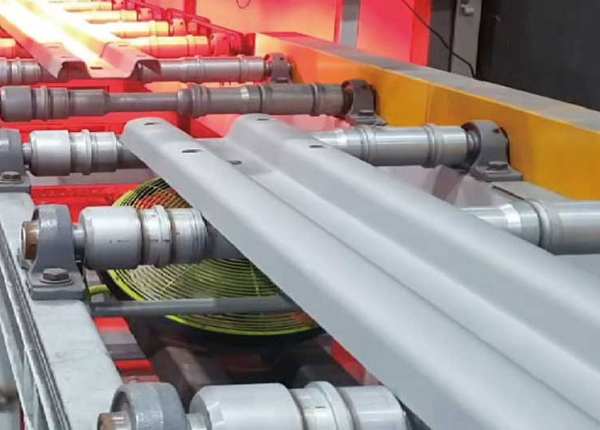

KEMP is a technology-centric corporation that develops environmentally friendly coating technologies and provides client companies with customized corrosion-preventing solutions. KEMP was the first to commercialize high-performance water-based inorganic galvanizing, developing water based field coating agents for maritime, shipbuilding, and road engineering applications.

KEMP is recognized across these industries with highly corrosion-resistant color coatings of various colors, recoating agents for corroded molten zinc coatings, coatings without elution of harmful heavy metals into water, and ultra-high corrosion resistance for immersion in sea water.

Outstanding Technology : KEMP commercialized eco-friendly alternative technology better than the hot dip galvanizing process causing environmental pollution, and has increased its market share at home and abroad through supplying the coating agents and methods according to a variety of applications such as automobile, shipbuilding, land/marine plants and road engineering.

Development of Green Technologies: KEMP, a company specializing in development and production of the eco-friendly coating agents, has contributed to the development and cost reduction of the coating industry based on its superb technology and development ability accumulated through ceaseless research and development. Also, KEMP developed the field spray coating agent first in Korea and is recognized as having its own technology.

Environmental solutions formetal corrosion prevention! KEMPWater Base Inorganic GalvanizingPerfectly environmentally-friendly, next-generation coating agent

Environmental solutions formetal corrosion prevention! KEMPWater Base Inorganic GalvanizingPerfectly environmentally-friendly, next-generation coating agent Welcome to KEMP Co.,LTD.THE NEXT GENERATION OF GALVANIZING.Commitment to people, businesses, and the future

Welcome to KEMP Co.,LTD.THE NEXT GENERATION OF GALVANIZING.Commitment to people, businesses, and the future Welcome to KEMP Co.,LTD.THE NEXT GENERATION OF GALVANIZING.Commitment to people, businesses, and the future

Welcome to KEMP Co.,LTD.THE NEXT GENERATION OF GALVANIZING.Commitment to people, businesses, and the future ECO PROJECT!Developers of innovative, environmentally-friendly technologiesCreating a world of harmony between nature and humankind.

ECO PROJECT!Developers of innovative, environmentally-friendly technologiesCreating a world of harmony between nature and humankind. ECO PROJECT!Developers of innovative, environmentally-friendly technologiesCreating a world of harmony between nature and humankind.

ECO PROJECT!Developers of innovative, environmentally-friendly technologiesCreating a world of harmony between nature and humankind.